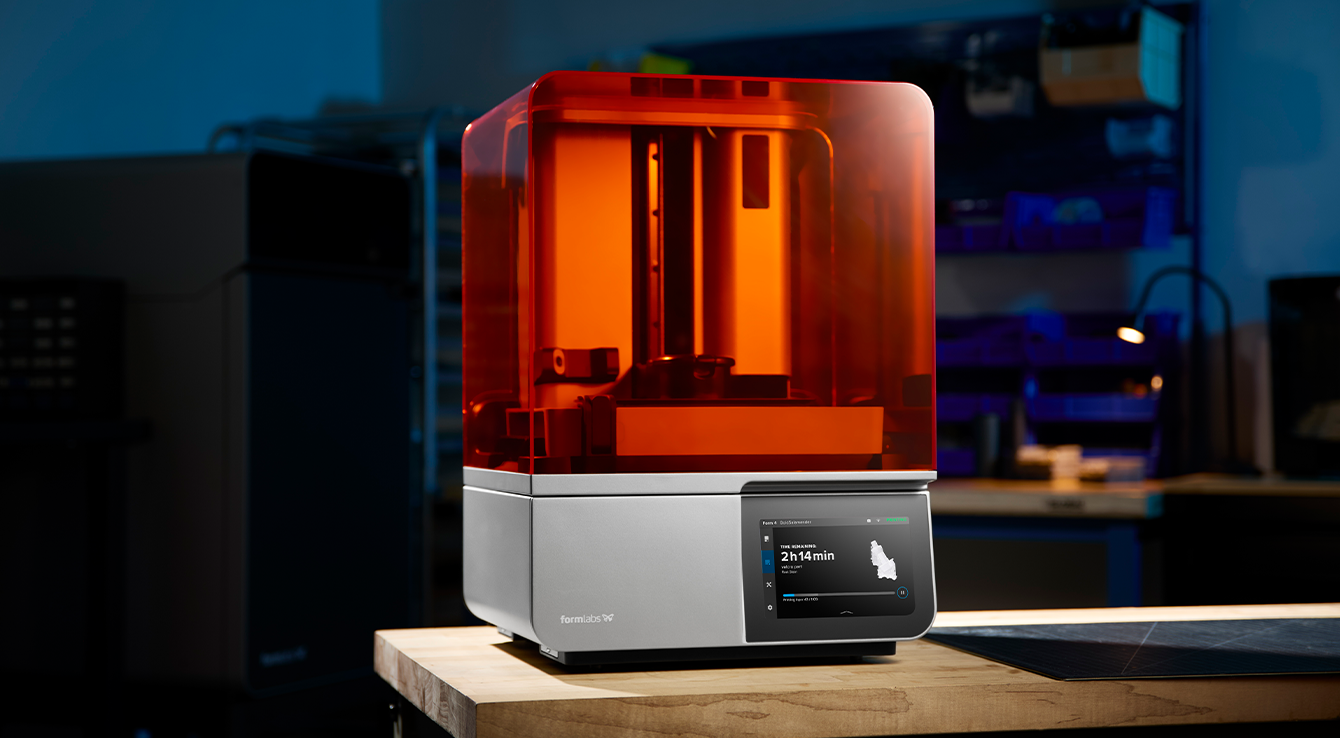

Next-Gen Fabrication: FormLabs Form 4

Speed Without Compromise

Time is the most valuable asset in production. The FormLabs Form 4 utilizes a new Low Force Display™ (LFD) print engine that drastically reduces print times compared to the Form 3 series. We are seeing print speeds up to 5 times faster, meaning a prop requested in the morning is ready for painting by lunch.

The ultra-fast draft printing allows for multiple iterations on a design in a day before moving to a more final finish, speciality or other process. As an example we can draft print until the design in perfect then mass produce in custom color resin or move to Carbon Fiber or Chrome Molly and even Stainless Steel on the Makerbot Method X!

Material Versatility

The Form 4's ability to switch tailored resins allows us to print:

- Clear (Yes Transparent) resin can be polished to near optical grade

- Flexible and Elastic

- Custom Color

- Ultra High Durability and Strength

On top of all of this, generally the amount of waste resin is low (the "rafts"). Because of the method of printing some amount of "post processing" must be performed to achieve the final part:

- Breaking away supports and sanding / removing support joints

- "Washing" with Isopropyl alcohol to remove excess resin

- A final high temp / UV cure phase

Incredible Reliability

The number of print failures encountered in hundreds of hours of usage is one. Just one... And to be honest, it was probably the operator (Rick Mark)'s fault. This is unbelievable compared to traditional FDM printing and in fact its so reliable we basically always use it for validation of parts before sending to the Makerbot Method X.